Thermo-Jack Freezer

Ideal freezing (or chilling) for all kinds of products!

The “Impinging jets are used in addition to the conventional air blast freezing system for a straight continuous tunnel freezing system that reduces freezing (or chilling) time from 1/2 to 2/3 of the conventional time.

This multi-purpose freezer has two types of conveyor belts – a mesh belt and a solid steel belt – making it suitable for a wide variety of products from liquid or granular products to bagged or unwrapped products.

The “Thermo-Jack Freezer” has shortened the freezing and cooling time of food to 1/2 to 2/3 of the conventional type by adopting impinging air. Even after freezing, the cells and quality can be maintained with fine micro ice crystals. In addition, features such as air defrost systems and CIP cleaning systems can be selected to improve production yields and minimize down time.

Conveyor belts can be selected from two types: mesh belts and flat stainless-steel belts. We have a lineup of IQF freezer suitable for a wide range of products such as liquid products, granular products, bagged and individually wrapped products.

Product Features

- Energy saving: less power consumption

- Quick freezing: Impingement Jet Air (patented)

- Quality freezing: No freezing burnt, less drip loss

- Hygienic Design: Cleanable design, Visible structure

- Reliable Capacity: Guarantee capacity, Based on actual freezing data

- Application: A wide range of product application

If you are looking for refrigerating equipment for various food processing in Thailand, please contact us.

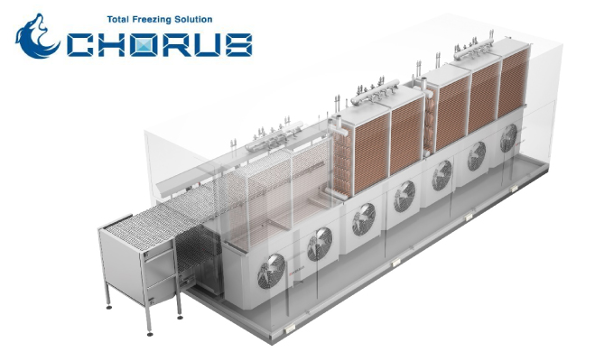

Fluidization Freezer (IQF Line Freezer)

Ideal for freezing vegetables, fruit and fishery products without clumping.(Capacity: 1,300 – 6,000 kg/hr.)

Strong air flow and vibration are applied from below, allowing rapid tunnel Freezing of products without clumping.

Specification of Slim Light Freezer

- Mesh belt

- Flat Stainless-Steel belt

A freezer for individually frozen cut vegetables, fruits, seafood, side dishes and with of the 5-20 mm of thickness. The products are frozen with a combination of two-layer conveyors. On the 1st conveyor, the surfaces are frozen while the products are separated by the blowing air from below and mechanical vibration, eliminating sticking between the products. They are then loaded in multiple layers on the 2nd conveyor for complete freezing.

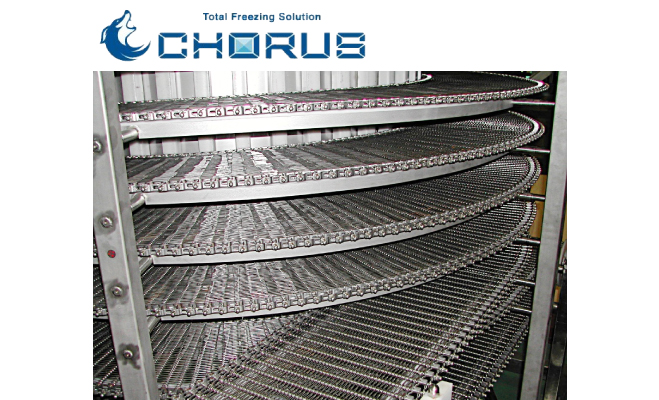

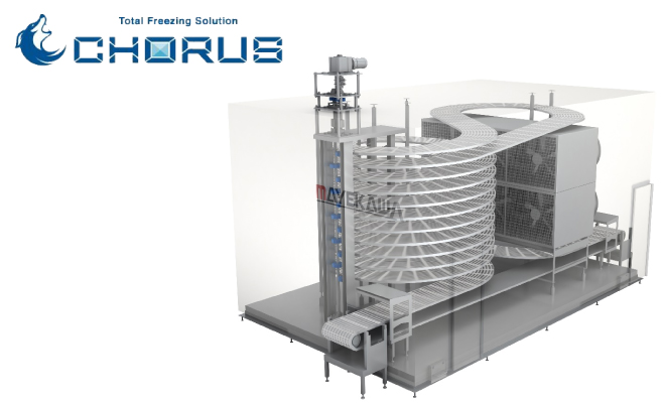

Multi layered freezer

Bottom loading and unloading possible from single tower. Can be used for flexible layouts.

Bottom loading and unloading possible from single tower. Can be used for flexible layouts.

While it has a spiral structure, you can freely design the direction and height of infeed and outfeed products, which facilitates a process layout in any way that fits easily into existing production line without an extensive modification for installation.

Product Features

- High space saving and flexible layout are possible

- Achieves highly efficient freezing

- Efficient air defrost system can be installed as an option

- Simple structure and easy operation. Improved visibility and cleanability

- Plastic belt can be selected as an option

- Up to 16 hours of continuous operation is possible

- Product design based on hygiene concept

- Achieves energy saving and cost reduction

- Easy to install equipment

Food that can be frozen and cooled

- Processed cooked food

- Bread, confectionery

- Pharmaceutical products

- Meat and fish products

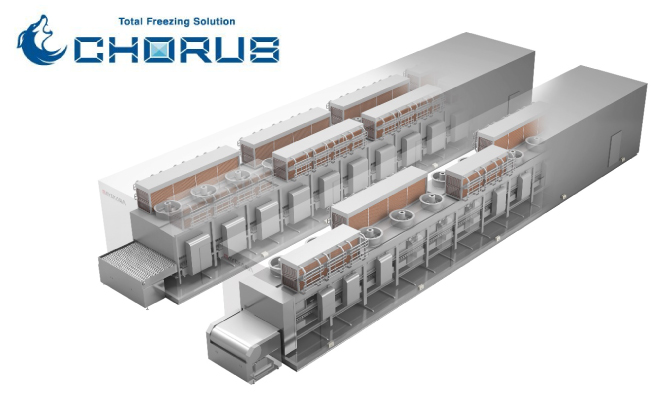

Spiral Freezer – continuous freeze apparatus

The conveyors are arranged three-dimensionally, allowing continuous freezing for mass production in a small installation space. This type can be used for all kinds of products.