Mayekawa (Thailand) Co., Ltd. is a distributor and service provider of deboning robots for chicken and pork, called DAS series. DAS series robot can debone each bone automatically and precisely. The popular robot is the TORIDAS MK-2, a robot that debones chicken legs automatically. Over 1,500 of Toridas units have been installed over 26 countries around the world.Mayekawa has succeeded in automating deboning robot technology. Since the development of “TORIDAS”, a fully automatic deboning robot for chicken whole legs, we have developed a lineup of various automatic deboning and bone separation robots “DAS series” that achieve high precision and high yields. If you are considering introducing automatic deboning and bone separation robots in Thailand, please contact us.

Mayekawa Co., Ltd. manufactures and develops deboning robots for chicken and pork in the DAS series, which are robots for deboning various chicken parts. In this article, we will introduce 3 models of robots for deboning all chicken parts as follows:

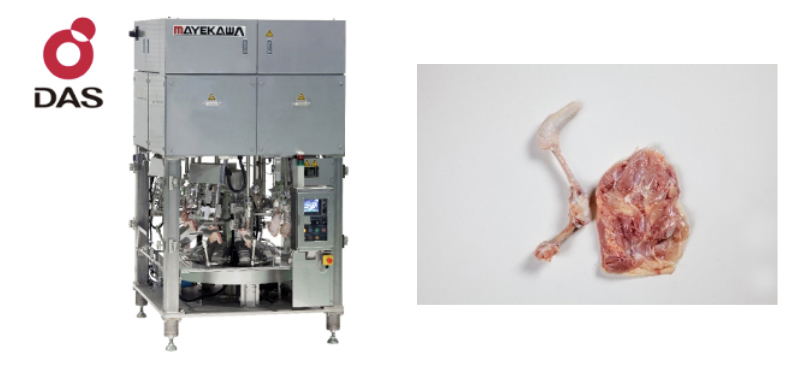

TORIDAS

The robot for deboning the bone in leg (BIL) can operate 4 times faster than speed of humans and are capable of automatically and precisely separating bone and meat.

It also ensures high productivity and high quality, and the most important thing is to reduce the number of employees in the production process as well.

“TORIDAS MARK II MT-04”, the flagship model of our automatic deboning robotics. Simply put the bone-in leg meat into the machine, and it automatically separates the bone and the meat. By fully automating the work that was previously done manually, we have shortened the work time and improved hygiene. Furthermore, by equipping it with an automatic slitting function and a final separation function as standard equipment, the yield can be equal to or higher than that of human hands. The automatic deboning robotics promote automation, labor savings and the cost reduction of food processing in Thailand. If you are interested in its introduction, please contact us. We have a training center for automatic deboning machines, and we also provide product training for our customers.

Product Features

- The inside of the equipment can be washed with hot water and sterilized with chemicals, making it hygienic.

- Two-stage measurement function enables cutting of bone-in leg meat at the optimum position

- Machine layout can be adjusted according to the amount of processing

- Stabilize production speed by image processing and input by robot

- Production of thigh meat and drum stick is possible (optional)

- Up to 5 units can be operated by one person by using the autoloader system (optional)

Brochure downloads TORIDAS MK2

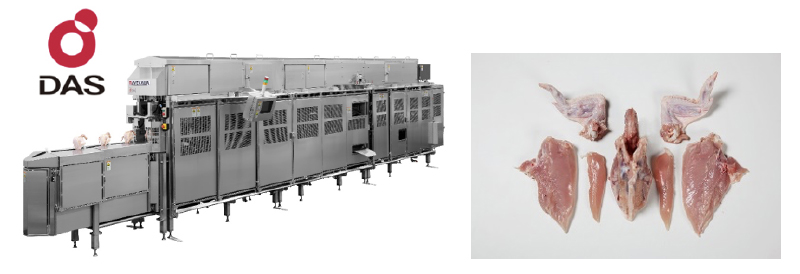

YIELDAS

AUTOMATED FRONT HALF DEBONING MACHINE CONSISTENT HIGH YIELD PERFORMANCE

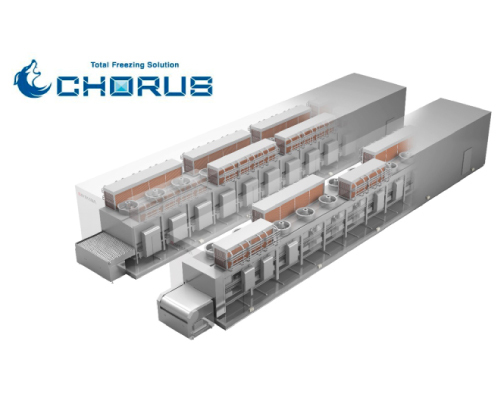

Impinging jets are used in addition to the conventional air blast freezing system for a straight continuous tunnel freezing system that reduces freezing (or chilling) time from 1/2 to 2/3 of the conventional time.

Automated measurement on front half, shoulder cut and tender removal have been achieved. The optimum cutting on each individually die rent front half can be achieved by image processing. Accordingly, automated segmentation into breast meats, wings, tenders as well as carcasses can also be made in a precise manner.

Measure the chicken individually by simply putting it into the equipment. Based on the image data, the cut position is automatically adjusted and separated into breast meat, wings, breast tenders, and carcass. It is possible to make an appropriate cut corresponding to the individual difference of each bird. In addition, maintenance work has been streamlined by consolidating integrated grease-up and various sensors. The structure is hygienic and easy to clean. If you are considering automation, labor savings, and cost reduction in food processing in Thailand, please contact us. We have a training center for automatic deboning equipment, and we also provide product training for our customers.

Product Features

- Optimal cutting is possible by individual measurement

- Automated slitting and breast tender removal

- Easy operation

- Quality equivalent to manual work

- Hygienic structure

WINGDAS

“WINGDAS” is Automated Chicken Wing Drumettes Machine. Either deboned chicken wing drumettes or deboned chicken tulips, also known as chicken lollipop wings can be produced.

In addition to separating the meat and bones of the wing drumettes, the simple switching adjustment supports tulip processing, which is time-consuming for manual work. Since it is equipped with an individual measurement function, even if the wing drumettes are put into the robot together, there is no problem in measuring and processing.

If you are considering automation, labor saving, and cost reduction in food processing in Thailand, please contact us. We have a training center for automatic deboning equipment, and we also provide product training for our customers.

Since it is equipped with an individual measurement function, even if the wing drumettes are put into the robot together, there is no problem in measuring and processing. If you are considering automation, labor saving, and cost reduction in food processing in Thailand, please contact us. We have a training center for automatic deboning equipment, and we also provide product training for our customers.

Product Features

- Automatically separates wing drumettes and bones

- Optimal cut of wing drumettes of different sizes by individual measurement

- Supports tulip processing

GIZZARD OPENER

Achieves highly efficient gizzard process! We are selling gizzard opener and gizzard processing equipment in Thailand.

Just align the orientation and set the gizzard, and it will automatically make a cut and open. In addition, it is equipped with an auxiliary skinner that removes the yellow skin, contributing to a reduction in the workload of the finishing process.

We promote automation and labor saving of food processing in Thailand. If you are interested in its introduction please contact us. We have a training center and also provide product training for our customers.

Product Features

- Easy work just by aligning and setting a gizzard

- Automatic cutting and removal of yellow skin is possible

- Can be combined with manual skinner (optional)