Mayekawa SCADA System

SCADA System by Mayekawa

Enhancing Efficiency and Safety in Industrial Refrigeration

Understanding SCADA – The Intelligent Monitoring and Control System

SCADA (Supervisory Control and Data Acquisition) is a system used for real-time monitoring and control of industrial processes. It enables operators to access operational data, analyze trends, and control equipment remotely, enhancing efficiency and reducing system risks.

Benefits

- 1. Improved Efficiency: Automated data collection

- 2. Enhanced Accuracy: Reduce reporting errors

- 3. Real-Time Monitoring: Instant visibility

- 4. Faster Decision-Making

- 5. Better Maintenance Management

- 6. Compliance & Reporting with historical data

Pain Point

Manual Data Recording:

High risk of errors, slow process

Slow Decision Making:

Data is scattered and not updated in real-time

Difficult Auditing:

Paper-based history is hard to track

Limited Scalability:

Hard to expand or integrate with ERP/MES/IoT

Time-Consuming Reporting:

Using Excel reports

High Labor Costs:

Manual data entry requires more manpower

Late Problem Detection:

Issues found after downtime occurs

Cannot Connect Machines:

No centralized monitoring

Benefits After the Addition SCADA

Automatic recording:

Data is accurate.

Real-time data:

Make decisions immediately.

Convenience:

Can monitor and control via SCADA from the office.

Data history (Historian):

Easy to search and analyze. Can integrate with ERP/MES/IoT systems.

Automatic reports:

Get results instantly. Easy Auditing.

Cost & time saving:

Save cost and time with SCADA.

Alarm / Problem alert:

Automatic alarm signals and log checking.

System security:

Continuous monitoring, reducing risk, and preventing problems.

Supervisory Control And Data Acquisition (SCADA)

SCADA integrates software and hardware to automate industrial processes.

It collects real-time data, enables monitoring, improves decision-making,

increases operational efficiency, and enhances production quality.

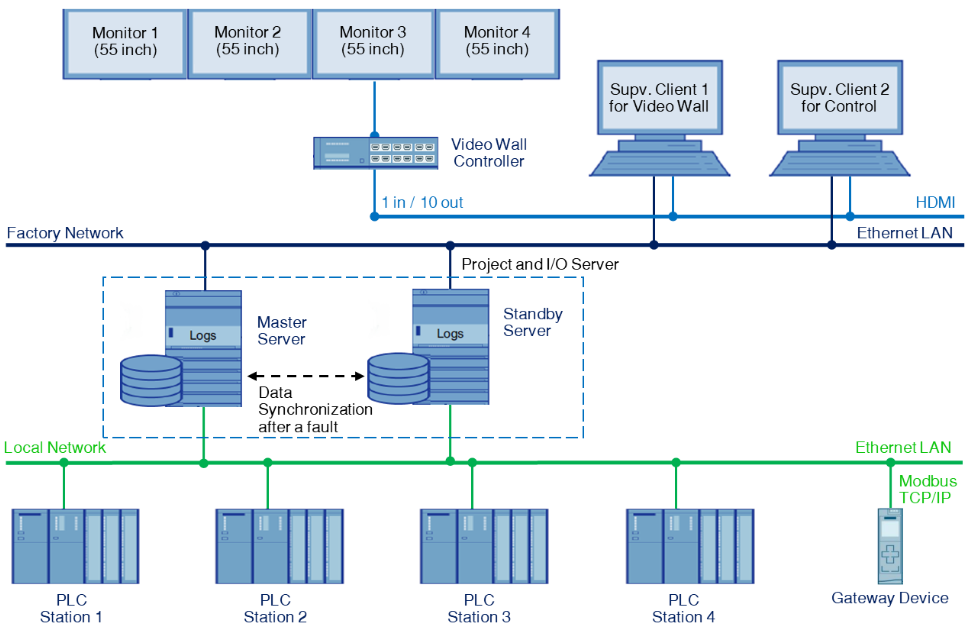

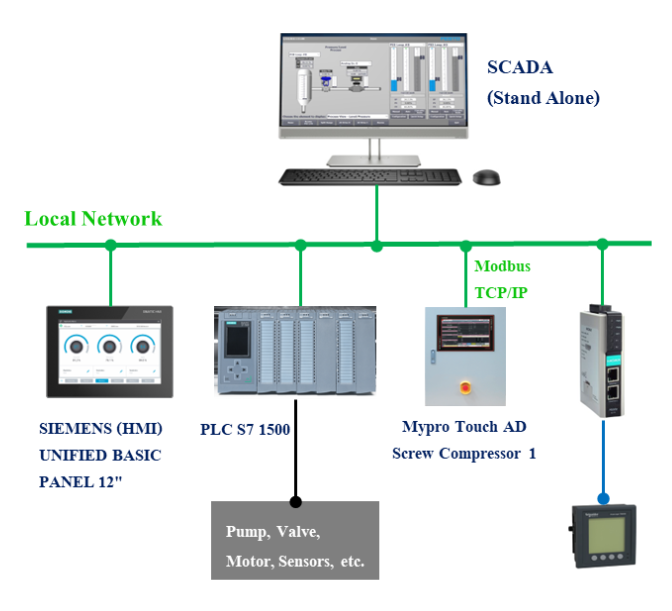

The Architecture of SCADA

- Master Station (Computer, IPC)

- Communication System (Modbus TCP/IP, OPC)

- Field Station (PLC, Controller, Sensors)

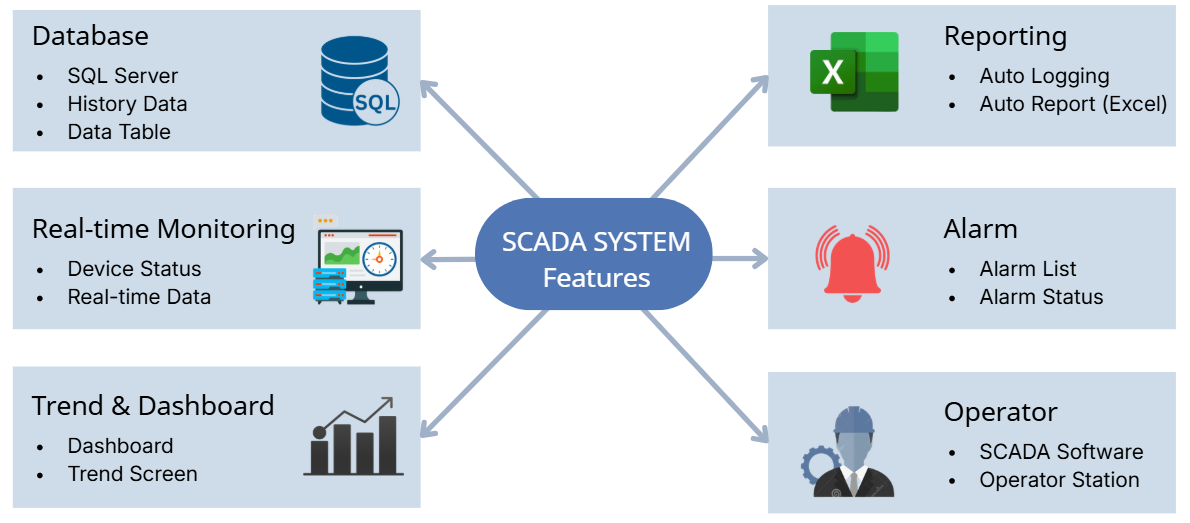

Main Features

- Real-Time Data Display: Voltage, temperature, etc.

- Trend charts & historical data

- Alarm system with notifications

- Database & event logging

- Alarm management: Reset / Acknowledge

- Export reports to Excel

Mayekawa SCADA Solutions

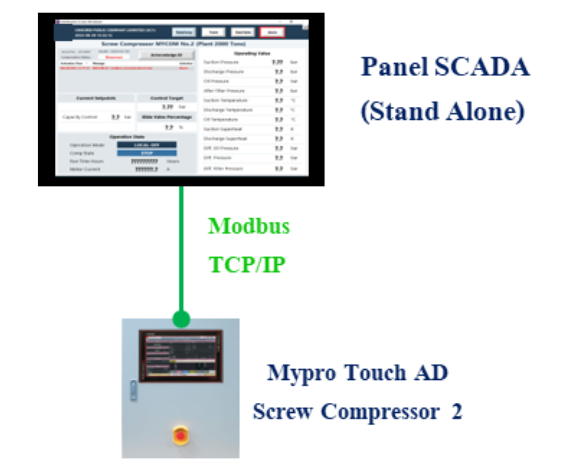

1

BASIC SCADA STAND ALONE

A closed-loop control & monitoring solution for factories requiring secure offline operation.

Reliable real-time monitoring and data logging for all Mayekawa equipment.

2

MINI SCADA STAND ALONE

A cost-efficient SCADA designed for small-scale systems.

Uses industrial-grade Panel PC with secured hardware and essential SCADA functions.

3

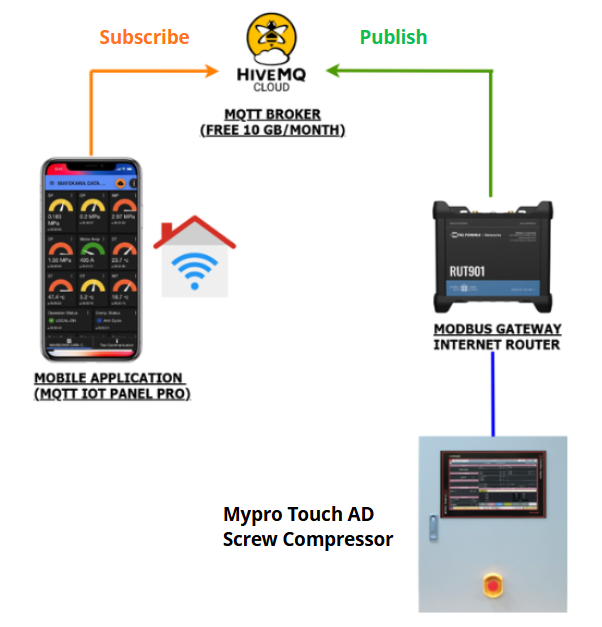

IOT MONITOR

Real-time monitoring from anywhere via cloud system.

Zero software licensing cost and can connect to MQTT broker easily.

4

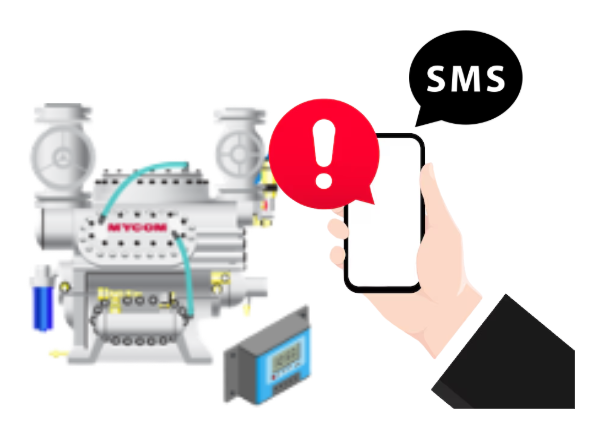

SMS NOTIFICATION

Get SMS alerts when machine issues occur—anytime, anywhere.

Alarm settings customized to customer needs.

STRENGTHS OF MAYEKAWA SCADA

- Flexible system: We can adjust and customize the SCADA to fit your factory and your process needs.

- Built by our own team: All PLC control and SCADA programming is done in-house by Mayekawa engineers.

- Fast problem solving: Because we develop everything ourselves, we can fix issues and make changes quickly.

- Reliable support: Our technical team provides full after-sales service and ongoing assistance.

📞 For more information: 095-408-1008

Contact: scada@mth.co.th