With years of experience in an overly competitive market in Thailand, Mayekawa’s refrigeration engineering has built successful in project business of food processing and cold storage in Thailand. Our engineering team incorporates the system required towards product and services of every customers’ facilities. Engineers are very progressive team and has been over the years delivering the best design and installation with highly satisfaction.

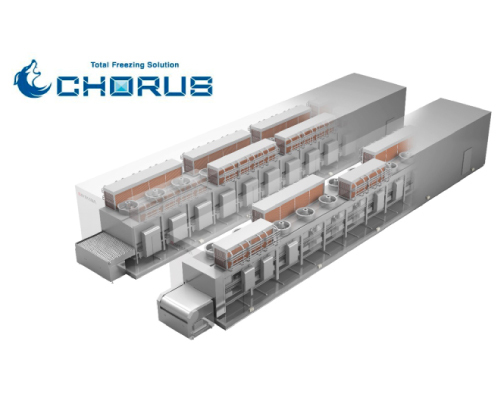

High-efficiency natural refrigerant refrigeration unit ‘NewTon’

Realizes high efficiency with a specialized design according to the application! We are selling high-efficiency refrigeration unit using natural refrigerants with excellent energy savings and environmental protection in Thailand.

“NewTon” was developed as an industrial refrigeration unit in consideration of global warming. By combining the natural refrigerant ammonia and carbon dioxide, the risk of ammonia leakage is minimized, and it enables high-efficiency operation and a reduction in power consumption.

“We contribute to environmental protection, energy saving, and reduction of running cost by realizing a better cooling and refrigerating environment for our customers and the global environment.

If you are considering a new facility of refrigeration / freezing equipment in Thailand, please contact us. We offer a wide variety of products to suit your application, such as refrigerated cold storage, chilling room and freezer.

Refrigeration Engineering

With years of experience in an overly competitive market in Thailand, Mayekawa’s refrigeration engineering has built successful in project business of food processing and cold storage in Thailand.

Our engineering team incorporates the system required towards product and services of every customers’ facilities. Engineers are very progressive team and has been over the years delivering the best design and installation with highly satisfaction.

Main product features

- Uses environmentally friendly non-fluorocarbon natural refrigerant

- Adopting a newly developed screw rotor profile that realizes high efficiency and low noise

- Equipped with an IPM motor with embedded permanent magnets to save motor power consumption

- Adopting shell and plate type heat exchanger

Main product lineup

- NewTon R: Dedicated for refrigerated cold storage

- NewTon C: Dedicated for ante room, chilled room and ice making factories

- NewTon F: Dedicated for IQF freezer

- NewTon S: Dedicated for ice skate rink

Pascal Air – Air Cycle Refrigeration System

Realizing the world of -100°C/-150°F degrees using only air as the primary refrigerant

Pascal Air and Pascal FC is a refrigeration system using the ultimate natural working fluid, Air. It compresses air, removes the compression heat, and expands the air adiabatically to cool a cold storage room or low temperature heat transfer fluid.

Pascal Air presents a revolutionary refrigeration unit employing an air refrigeration cycle, capable of achieving an ultra-low temperature range from -100 to -50℃. Unlike conventional systems, Pascal Air utilizes the surrounding air, which boasts zero ozone depletion potential and zero global warming potential, thus making it environmentally friendly.

Operating within this ultra-low temperature spectrum offers significant energy savings of up to 50% and a notable reduction in CO₂ emissions compared to traditional vapor compression refrigeration systems. Beyond its primary application in cold storage for preserving tuna and bonito, Pascal Air finds versatile use across various sectors requiring ultra-low temperatures, including continuous freezers, shredding for household appliance recycling, semiconductor manufacturing processes, and freeze medical/pharmaceutical manufacturing and storage.

Remarkably, installation in cold storage necessitates only a cold air outlet and intake duct, eliminating the need for an air cooler within the storage space. This eliminates heat load from fan power and minimizes heat exchange loss from frost. Additionally, moisture adhering to stored items is managed within the refrigeration unit, eliminating the need for defrosting and the associated heat input into the cold storage. examined, increased storage capacity is achievable as there’s no requirement for space typically allocated to air cooler installation in conventional systems. Furthermore, benefiting from a natural convection design, Pascal Air ensures even temperatures throughout the cold storage, preserving the quality of stored items impeccably.

ADVANTAGES

- Eliminate evaporators, air coolers and fans from the freezer

- No defrosting of freezer space or in-room equipment required

- Reduce power usage by up to 40% compared to cascade systems

- Eliminate additional heat load from auxiliary equipment

- Vastly simplified installation using air ducting only

- Improved safety through elimination of traditional refrigerants

- No piping of primary or secondary refrigerants required (For Pascal Air system. Pascal FC system requires secondary brine piping.)

APPLICATIONS

- Cold storage for tuna/oceanic bonito

- Chemical cooling processes

- Food product rapid freezing

- Vacuum Freeze-drying

- Semiconductor manufacturing processes

- Industries requiring ultra-low temperatures

– Pharmaceutical

– Hospitals

– Physics/chemistry fields