Sustainable application for a green energy transition

Carbon Capture and Utilization (CCU)

CCU is a technology that captures carbon dioxide without releasing it into the atmosphere and reuses it in various ways.

Carbon recycling is a technology that can contribute to both global warming countermeasures and effective resource utilization, and is thought to play an important role in realizing a decarbonized society.

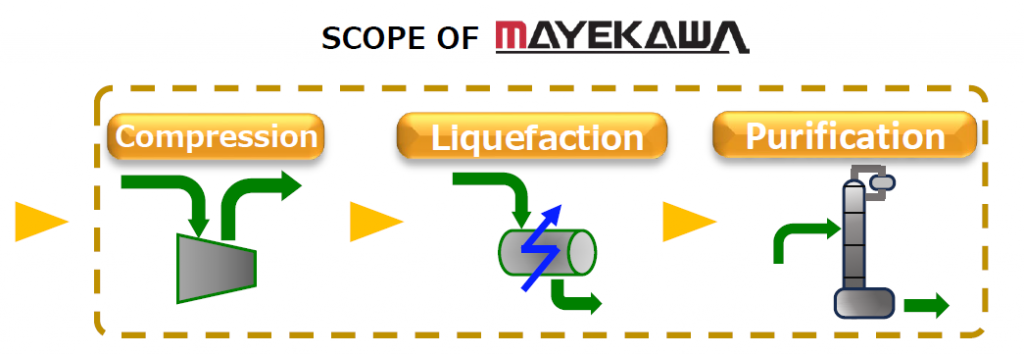

The carbon capture technologies include innovative ways to reduce CO₂ emissions through processes aimed at capturing, purifying, and liquefying CO₂. MAYEKAWA solutions are available for the compression of CO₂ from small to large flow rates (up to 30 tons per hour for package systems).

In addition, MAYEKAWA refrigeration units with ammonia, a natural refrigerant, can be installed in the stage of the process for liquefying CO₂. The liquefied CO₂ can be transported for applications in the food industry or in the chemical industry (e.g., to produce carbonated beverages).

Carbon Dioxide Capture, Utilization and Storage

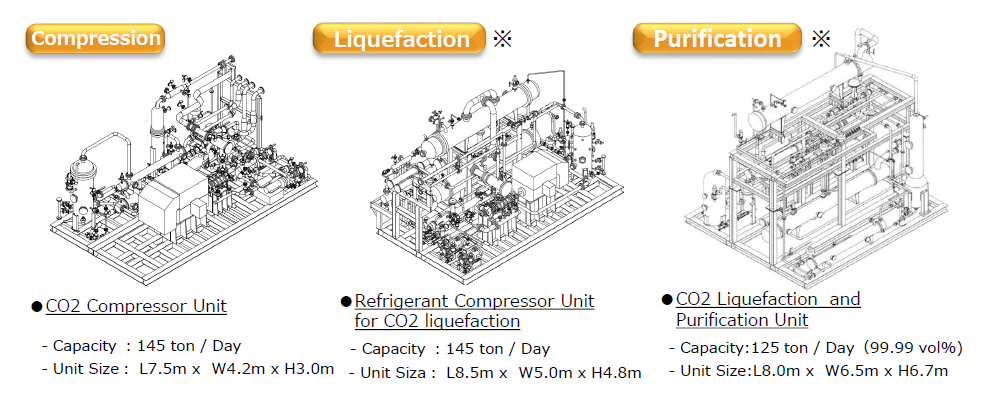

MAYEKAWA can handle a wide range of processes, from compressing, liquefying, and purification of CO₂ after capture.

CO2 capture from On-land /Board facility

Mayekawa can handle a wide range of processes, from compressing,

liquefying, and purification CO2 after capture.

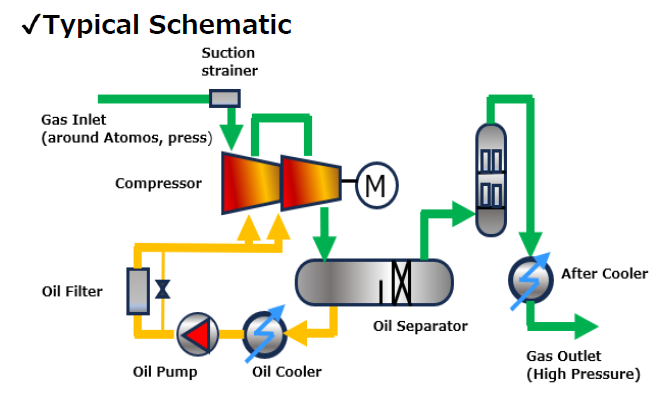

CO2 Compressor Unit

CO₂ Compressor Unit

Unit Contents:

- Compressor Unit (incl. Lubrication system)

- After Cooler

- Flow Range: 100 – 17,800 m³/h

- Discharge Pressure: ~25 bar, ~50 bar

- Oil Carry Over: Min. 0.01 ppmwt

- High Maintainability

- Flow control using internal slide valve

- Applicable for wide flow range

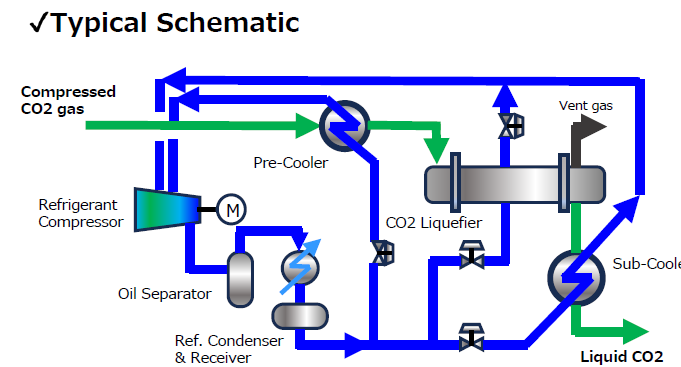

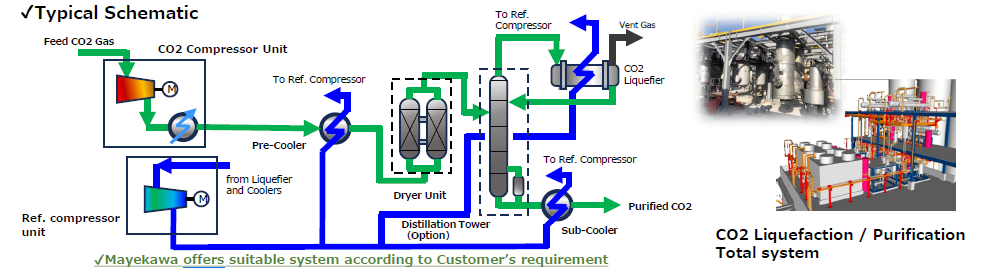

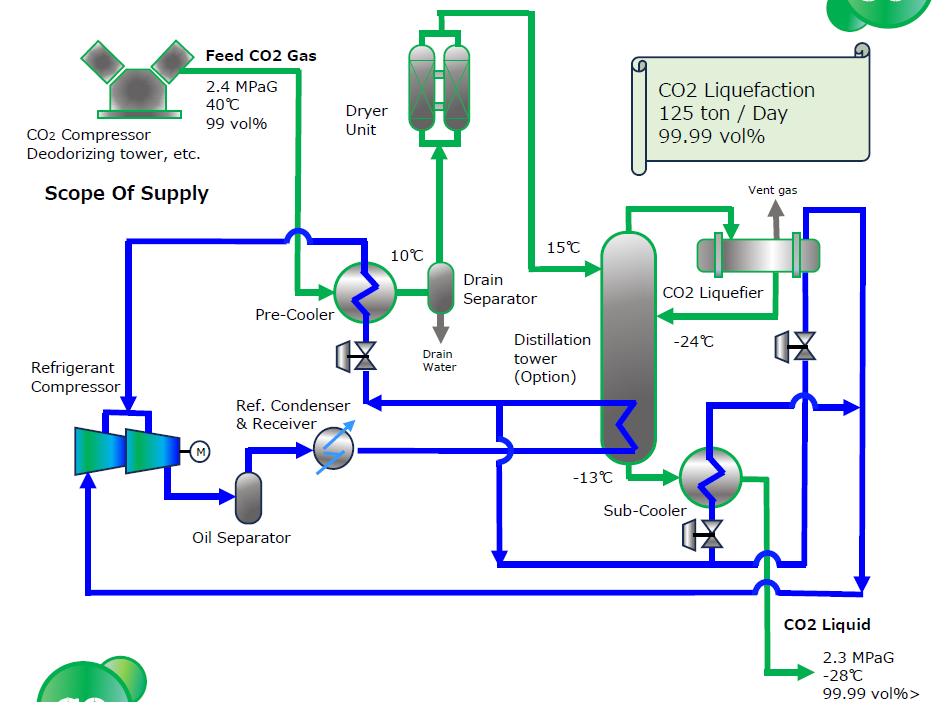

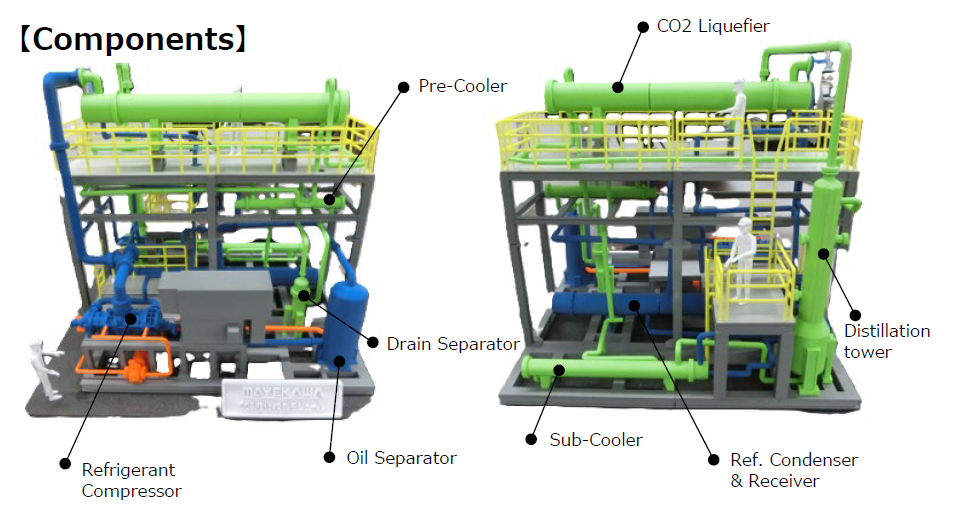

CO2 Liquefaction system

Refrigerant Compressor Unit

System Consists

- Refrigerant Compressor Unit (incl. compressed lubrication system)

- Refrigerant Condenser / Receiver

- Pre-Cooler

- CO₂ Liquefier

- Sub-Cooler

Design and customization according to process requirements.

Possible to offer the system with environment-friendly refrigerants such as NH₃ and Hydrocarbon (natural refrigerants).

Total system including CO2 Compression, Liquefaction and Purification

※Not included CO2 Compressor Unit and Dryer Unit.

【Delivery record ※For reference】

Delivery Records (For Reference)

| Customer | Purpose | Year | Capacity |

|---|---|---|---|

| Japan Gas Company | Liquefaction & Purification | 2000 | 125 Ton / Day |

| Japan Beverage Company | Liquefaction & Purification | 2002 | 22 Ton / Day |

| Japan Beverage Company | Liquefaction & Purification | 2003 | 22 Ton / Day |

| Japan Oil & Gas Company | Liquefaction | 2005 | 432 Ton / Day |

| Japan Oil & Gas Company | Compression & Liquefaction | 2011 | 145 Ton / Day |

| Japan Gas Company | Liquefaction | 2018 | 36 Ton / Day |

| Japan Liquid Charcoal Company | Liquefaction | 2020 | 216 Ton / Day |

| Thailand Oil & Gas Company | Compression & Liquefaction | 2014 | 300 Ton / Day |

| Thailand Oil & Gas Company | Compression | 2018 | 100 Ton / Day |

| Oversea Oil & Gas Company | Compression & Liquefaction & Purification | 2012 | 150 Ton / Day |

| Oversea Oil & Gas Company | Compression & Liquefaction & Purification | 2019 | 60 Ton / Day |

| Oversea Dry Ice Company | Liquefaction | 2020 | 326 Ton / Day |

| Oversea Oil & Gas Company | Compression & Liquefaction & Purification | 2013 | 150 Ton / Day |

| Oversea Gas Company | Compression & Liquefaction & Purification | 2023 | 120 Ton / Day |

| Oversea Energy Company | Compression & Liquefaction & Purification | 2023 | 300 Ton / Day |

| Oversea Shipbuilding Company | Liquefaction | 2024 | 25 Ton / Day |

These records are just a small part of the whole thing.

Mayekawa designs units and systems according to the application and customer requests.

Please feel free to consult us.