Mayekawa (Thailand) Co., Ltd. provide energy-saving and environment-friendly machines to our customers. Furthermore, Mayekawa also provide equipment that increases energy-saving effects and products that keep customers’ equipment in good condition. For more detail information, please contact to Mayekawa (Thailand).

After Sales Service (Overhaul and Maintenance)

In order to use MYCOM compressor in good condition for a long time, Mayekawa strongly recommend you overhaul and maintenance by Mayekawa’s experts with MYCOM genuine parts! Mayekawa (Thailand) stock all standard parts for MYCOM compressors. For inquiries regarding overhaul and maintenance, please contact Mayekawa (Thailand).

MYCOM OIL for compressor

MYCOM A-1 is a high performance hydrocracked iso-dewaxed paraffinic base oil designed for ammonia applications.

MYCOM A-1 has high thermal stability for improved resistance to oil break down and extended service intervals.

MYCOM A-1 brings high efficiency to system due to special formulation with advanced seal conditioning and self-cleaning additive system to minimize seal leakages for old system and also prolong system internal cleanness free of sludge.

MYCOM A-1 has optimum viscosity providing better compressor lubrication and minimizes oil carry over with very low foaming technology.

Mayekawa (Thailand) propose following three kinds of compressor oil.

1. MYCOM A-1 Hydrocracked iso-dewaxed paraffinic base oil designed with self-cleaning additive.

2. MYCOM A-2 Hydrocracked iso-dewaxed paraffinic base oil designed without self-cleaning additive.

3. MYCOM-ZERO Fully synthetic PAO (Polyalphaolefin) base oil.

Please refer to the attached brochures. If you need further information, please contact to the office of Mayekawa (Thailand).

Thermo-Shutter

Feature 1. Stable storage temperature ensures product quality.

Feature 2. Less condensation and frost in a cold storage decreases the defrost frequency.

Feature 3. Prevention of heat loss reduces power consumption.

Thermo-shutter has been adopted in a number of industries to high praise, including cold storage, logistic centers and loading docks. The table shows an energy reduction by adopting the product.

With the ever advancing small-lot, high-demand delivery, doors in cold storage are opened more frequently. Thermo-Shutter provides reliable heat shield performance that solves these problems.

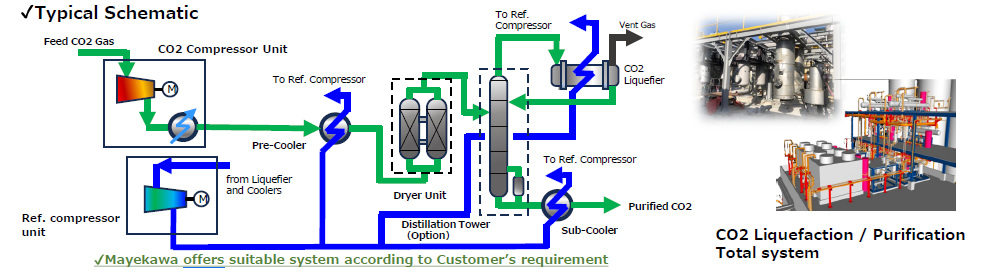

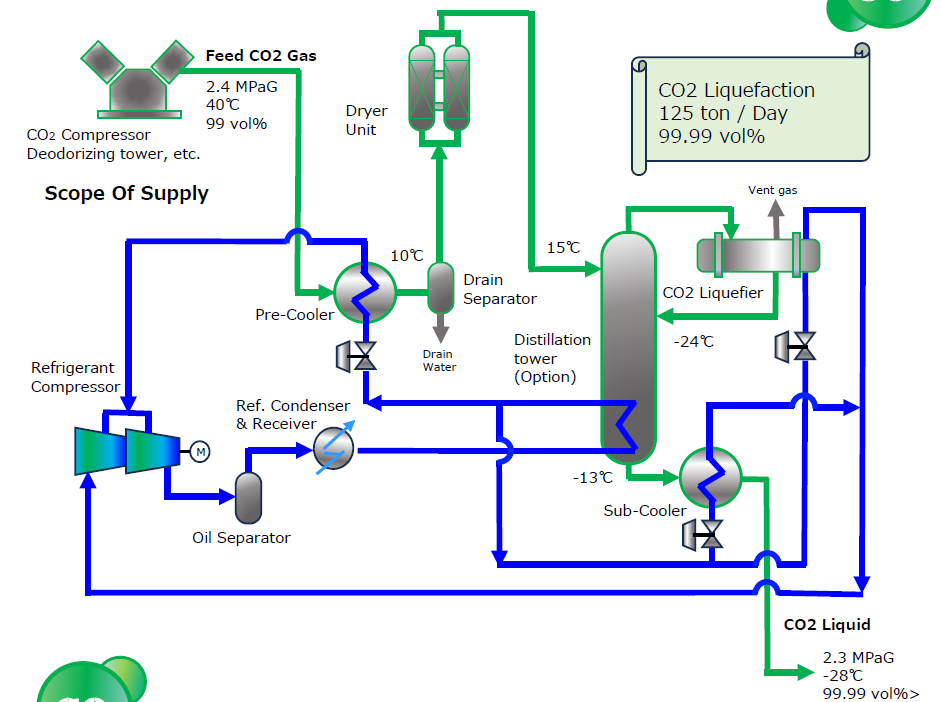

Carbon Capture and Utilization

The carbon capture technologies include innovative ways to reduce CO2 emissions through processes aimed at capturing, purifying and liquefying CO2. MAYEKAWA solutions are available for the compression of CO2 from small to big flow rates up to 30 ton per hour for package. In addition, MAYEKAWA refrigeration units with ammonia, a natural refrigerant can be installed in the stage of the process for liquefying CO2. The liquefied CO2 can be transported for applications in food industry or in the chemical industry (e.g. to produce carbonated beverages).